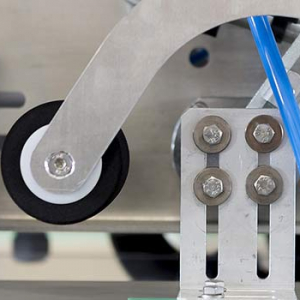

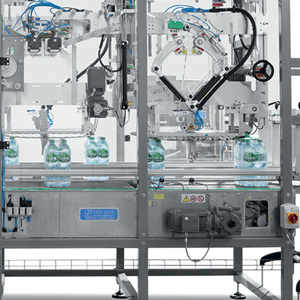

Progettazione e realizzazione di macchine confezionatrici e packaging automation

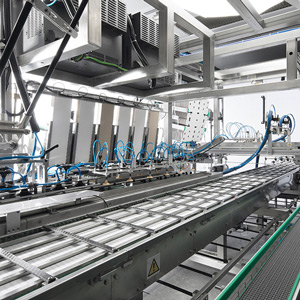

Sistemi di automazione e macchine speciali per l’imballaggio.

Manigliatrici, macchine automatiche per il multipack, macchine per confezionamento robotizzate e tutto ciò che può servire per l’imballaggio secondario.

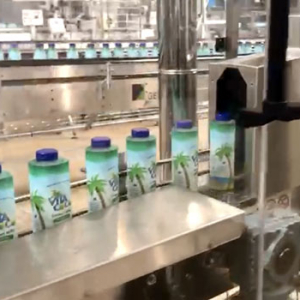

Soluzioni per l’imballaggio di numerose tipologie di prodotti, in particolare beverage, food, dairy e tissue.

Vai alla sezione dedicata ai prodotti e scopri quale macchina può fare al caso tuo.